The Machines That Build The Machines

What is a Gigafactory? Well, the prefix “Giga” is generally used to denote “billion” but, in this case it just seems to mean HUGE. No word on why they didn’t just call them UberFactories. Except, maybe the ride-share folks would have a problem with that since, you know, Tesla will be competing with them in the not-too-distant future.

Elon Musk calls it the “machine that builds the machine”. And, somewhere in that I think he’s acknowledging that while the car, itself may be complex and a modern marvel of engineering, the factory that builds them is far more difficult to design. After all, if you are shooting for a carbon-neutral future, you can’t do it the way it’s always been done. Here’s some interesting info about Tesla’s main factory and the GigaFactories they’ve built since.

The Fremont Factory

Tesla started the manufacture of model S in their Fremont, California factory. Though not considered a gigafactory, it provides 3.5 million square feet of office and manufacturing space sitting on 370 acres of land. It employs 10,000 people making Tesla Models ’S’, ’X’ and ‘3’. In addition to the human employees working at the plant, Tesla uses over 160 robots, ten of which are the largest robots in the world and are named for X-men characters (Xavier, Iceman, Wolverine, Beast, Storm . . . you get the picture). If this sounds impressive, hold onto your magneto. In 2016, they applied for and received approval from the city of Fremont to double the size of the plant to 10 million square feet in order to support the growth of their production volume to a target of 500,000 vehicles per year (10,000 per week). Who knows. When the expansion’s complete perhaps there’ll be room for some robots from the Marvel Comic Universe in there. Ironman, I’m talking to you! (Oh, Calm down! I know Ironman’s not a robot.)

Gigafactory 1

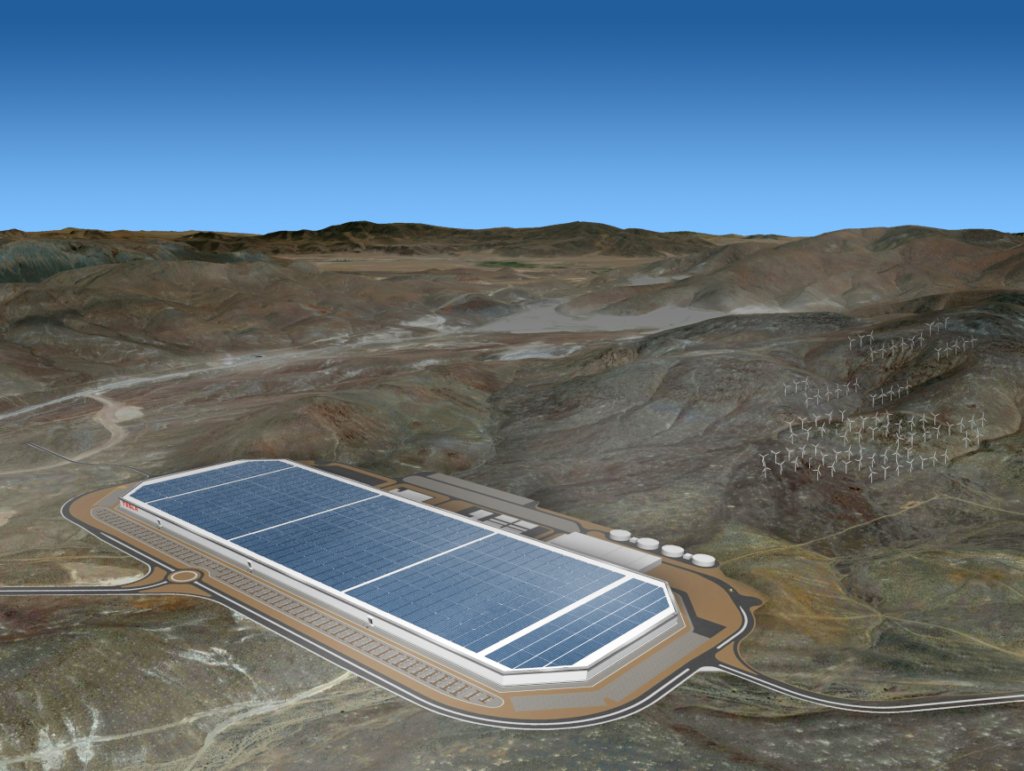

In order to grow the production of Tesla vehicles at the rate Elon wanted to, it would be necessary to also grow the production of the the lithium-ion batteries that power them. Also, to meet Teslas stated goal to accelerate the world’s transition to sustainable energy, the cost of batteries needed to come down. With those things in mind, Tesla and Panasonic began construction of Gigafactory 1 in Sparks, Nevada in January of 2015. The giant factory would build and supply batteries not only for Tesla vehicles but also for Tesla’s energy products, the Powerwall and Powerpack. In addition to this, the factory would also produce electric motors for Tesla cars.

The factory has a footprint of 1.9 million square feet providing 5.3 million square feet of office and manufacturing space across several floors. And here’s where they needed to start doing things differently because factories with large geographic footprints generally come with large carbon footprints and that’s antithetical to Tesla’s mission. So, they planned from the very start for this factory to be completely self-sustaining through the use of renewable energy only. When the factory is completely built out, it will be powered primarily by solar panels installed on the factory roof combined with other wind and geothermal energy sources. The roof will support 200,000 solar panels (70 MegaWatts of electricity) that, paired with adequate battery storage will supply most of the power required by the factory and will constitute the largest rooftop solar installation anywhere in the world.

Inside the factory, excess heat generated by manufacturing equipment is used to keep the building warm in the winter. (On a side note, did you know that the Mall of America in Bloomington, Minnesota has no heating systems, despite frequent sub-zero winter temps in the area? It’s heated entirely by excess heat from lights and fixtures and heat from the bodies of shoppers! Seriously. Look it up.) Some of the equipment requires chilled water for cooling so Tesla also makes use of a heat-pump type system to reduce the energy cost of chilling that water. Dry air is required for many processes and the desert location allows them to greatly reduce the need for humidifiers by pulling air in from the surrounding desert. All this and the obvious choice of using LED lighting throughout the plant not only reduces their carbon footprint, it also reduces their overhead making it easier to manufacture batteries (the big ticket item in any EV) at a much lower cost than previously thought possible.

Gigafactory 2

This factory is located in Buffalo, New York. The plant makes solar panels and was acquired when Tesla bought SolarCity in 2016. Solar panels. I have them on my house. They’re cool and rad insofar as they can be used to recharge Tesla cars but otherwise . . . nothing to see here . . . moving along . . .

Gigafactory 3

Located in the Pudong District of Shanghai, China, this factory was built in just ten months! You can view a time-lapse video of the construction here. The Shanghai factory will build Tesla Model 3 and Model Y cars for the Chinese market – clearly the largest EV market in the world. Model 3 cars went on sale Friday, November 22, 2019. Model Y will follow sometime next year. Tesla has already seeded a network of 2,000 superchargers in China to get things rolling (so to speak).

Gigafactory 4

Slated to be built in Grünheide, Germany (just outside Berlin) there’s not much else known about the future factory at this time. It is assumed, however that it will not please the folks at Bavarian Motor Werks to have a Tesla factory in their backyard. BMW is one of the companies whose sales have been most impacted by the Tesla Model 3. Alas, I expect they will catch up soon. They’ve got some excellent engineers at BMW, as well. It’s unfortunate they didn’t get on board the EV train back in 2012 along with Tesla . . . and Elon.

For useful tips and information based on real world experience with the Tesla Model 3 check out He Said, She Said Tesla Model 3 User’s Guide. (Link in image.)